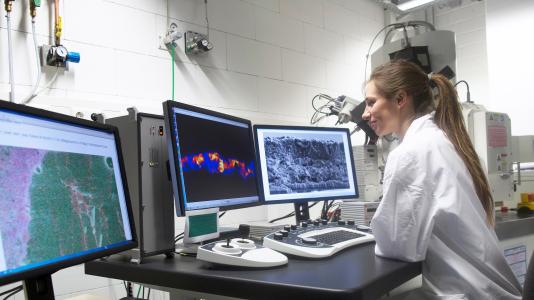

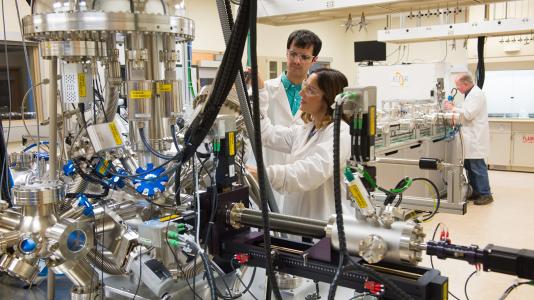

The Center for Nanoscale Materials

The Center for Nanoscale Materials (CNM) at Argonne is a DOE Office of Science user facility providing researchers from across the globe with world-class expertise and instrumentation for multidisciplinary nanoscience and nanotechnology research.

Academic, industrial and international researchers can access CNM through our user program for both nonproprietary and proprietary research. Access is provided at no cost to users for research that is in the public domain and intended for publication.

Learn More about the CNM

Research Highlights

Observation of metastable precipitation in liquid-liquid extraction processes

In a PNAS paper, researchers provide a deeper understanding of how precipitation may occur during liquid–liquid extraction to separate critical elements, process nuclear waste, and remediate the environment.

2D ionic liquid behavior of charged rare-earth clusters on a metal surface

In an Advanced Science paper, researchers used scanning tunneling microscopy to investigate the structural and electronic properties of 2D rare-earth clusters on a one-cluster-at-a-time basis.

Unexpected electronic properties revealed in the dichalcogenide, tantalum disulfide (1T-TaS₂)

In a Physical Review B paper, researchers address ongoing debate surrounding the electronic properties of tantalum disulfide by employing resonant inelastic X-ray spectroscopy combined with first-principles calculations.

Meet Our Leaders

Ilke Arslan

Division Director

Gary P. Wiederrecht

Deputy Division Director

Nathan P. Guisinger

Group Leader - Quantum and Energy Materials/Scientist, Nanoscience

Martin V. Holt

Group Leader - Electron and X-ray Microscopy/Scientist, Nanoscience

Constance R. Pfeiffer

User Program Manager

Subramanian Sankaranarayanan

Joint Appointment/ Group Leader, Theory and Modeling Group

Richard D. Schaller

Physics Leader 1

Anirudha V. Sumant

Group Leader - Nanofabrication and Devices/Materials Scientist, Nanoscience